3D for all

The use of 3D printing continues to rise among students and researchers. ETH Zurich has set up a special web platform so people will be able to find the right printer faster in future. At the same time, the ETH Additive Manufacturing Community has also been created, forming a place where researchers can exchange ideas on the various applications of 3D printing.

“The potential of 3D printing is far from being exhausted; the proper use of this technology is still only in its infancy.” That is the firm belief of Mirko Meboldt, professor of product design and construction at the Institute of Design, Materials and Fabrication. What is lacking is applications for 3D printing. Despite the technology being known for 30 years, for a long time it only had a niche following. Only once the media presented additive manufacturing technology under the name ‘3D printing’ to a broader audience did its use start to spread. Today it is even possible to buy 3D printers for personal use in electronics stores.

Community for exchanging experiences

Mirko Meboldt is creating the ETH Additive Manufacturing Community in order to promote the exchange of knowledge within ETH Zurich. The kick-off event will take place on 23 September (see box for details). “Up until now, each user has done their own thing and found their own, individual solutions,” Meboldt explains. “We want to use this community to network this expertise and simultaneously promote research and innovation.” The community will also have a web platform. The aim of this online service is to bring the owners of 3D printers together and make it easier for researchers and students to access these devices.

Matthias Baldinger, research assistant at ETH Zurich and CEO of Additively AG, is responsible for the technical implementation of this web platform. Additively is an ETH Zurich spin-off project that developed a commercial 3D printing platform last year. An online service has now been created especially for ETH Zurich using this platform, and the platform for 3D printers is embedded in a larger university project. Daniel Müller, vice president of human resources and infrastructure, is coordinating the creation of a virtual platform for the larger workshops available at ETH Zurich and their machinery. This is intended to improve knowledge management within the university and promote synergies in the procurement of new machinery and materials.

Web platform for 3D printers

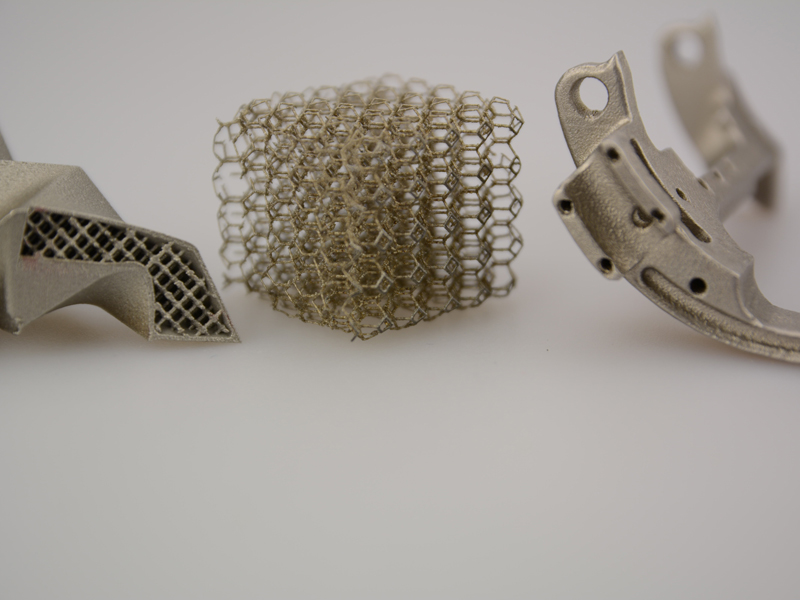

The external pageplatform for 3D printerscall_made has been online since the end of 2014. Staff and students of ETH Zurich can use the platform to access printers both within and outside of the university. “We have connected 22 printers at ETH Zurich to the platform so far, as well as around 300 external providers”, says Baldinger. There are five technology groups for 3D printing available at ETH Zurich: laser sintering, laser melting, stereo lithography, photopolymer jetting and fused deposition modelling (FDM). Users can choose from any of 27 different materials, including plastics, metals and resin. Another 250 materials are also available from external providers, ensuring that the perfect solution can always be found for every application. “The goal is that the maximum possible number of ETH Zurich’s 3D-printed parts can be acquired via the platform,” Baldinger says. “Even users who already know their suppliers should ideally submit their requests via the platform in future.”

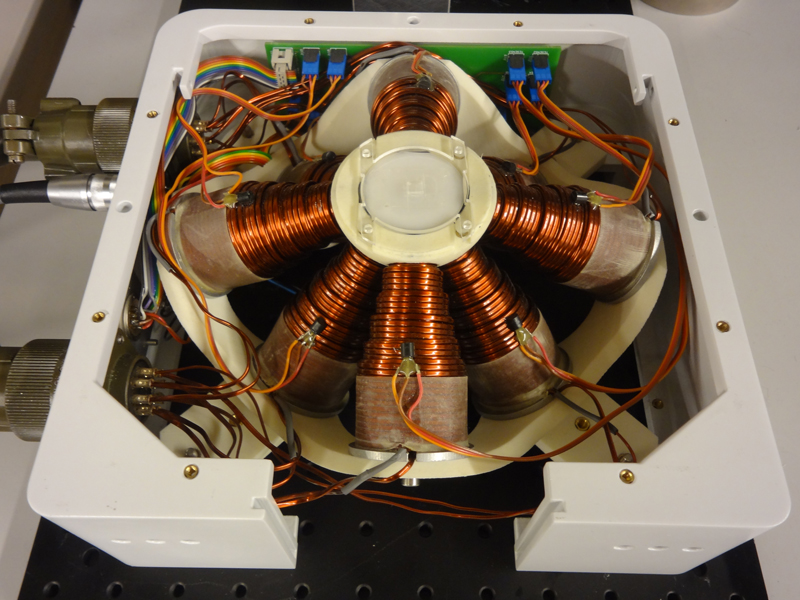

So far, researchers’ printers have been used for the production of special parts in an experimental setup or in bioengineering for implants and cells. “3D printing is particularly well suited when components must be produced in small runs, but industrial production would be too expensive because of the small number required,” Baldinger explains. This is how the ETH Zurich spin-off project MagnebotiX 3D-printed all the external pageplastic parts for its microbotics systemcall_made, including the housing. Other important applications include mechanical and electrical engineering. In these cases, 3D printing can be beneficial where parts of the production process are digitalised. 3D printing also opens up entirely new design processes and aesthetics in the field of architecture.

3D printing for staff and students of ETH Zurich

The new platform works as follows: 3D printers belonging to ETH Zurich and 300 external providers are listed together with their services at external pagewww.additively.com/ethcall_made. Those who already know which technology they would like to use to manufacture something can simply go online and select one of ETH Zurich’s own providers or an external provider and get a quote. Anyone who is unsure which technology is best-suited to their project can send a request, which is received by Additively. The Additively team will then advise on the selection of the right material and printer.

Kick-off event for the ETH Additive Manufacturing Community

The kick-off event for the ETH Additive Manufacturing Community will take place on 23 September 2015 in the main building at ETH Zurich. The event will provide an initial overview of activities relating to 3D printing at ETH Zurich. The event will start at 3 pm and from 5 pm onwards there will be a small reception and an opportunity to network and exchange experiences.

Are you interested in additive manufacturing or 3D printing? Register now via email:

Would you like to be involved in the kick-off event? Get in touch and briefly tell us about your 3D printing project:

3D printing at ETH Zurich

-

Elegant shapes: three examples of 3D-printed metal objects (Photo: PDZ) -

“The potential of 3D printing is far from being exhausted,” says ETH Zurich professor Mirko Meboldt. (Photo: PDZ) -

One example of how the ETH Zurich spin-off project MagnebotiX makes use of 3D printing technology: an open system with 3D-printed components. (Photo: MagnebotiX)