The multitasker

Developing new things together and effecting change – that's what gets Moritz Mussgnug out of bed in the morning. The mechanical engineer manages to juggle his doctoral thesis with a startup and a project to optimise the production of walnut oil for people in Nepal.

Studying towards a doctorate at ETH Zurich would be enough for most people, especially if they were also father to a 10-month-old daughter. But not Moritz Mussgnug. Alongside his academic work on mobile eye-tracking in ETH Professor Mirko Meboldt's group, the 31-year-old is also co-founder of startup Memox and project coordinator at MITO. Through the development of a new machine, this joint project with Swiss development organisation Helvetas aims to support Nepali farmers by making the production of Nepal's much-loved walnut oil quicker and easier.

All this doesn't just mean a lot of work – each of these projects requires a different skillset and diverse expertise. But if it were up to Mussgnug, he would be juggling even more projects. "For the sake of quality and my family, I've had to learn to limit myself to a few projects," he says.

Nepal trip leads to research project

The story of the MITO walnut oil project shows just how difficult this is for him. In autumn 2015, Mussgnug wanted to go to Nepal to visit his wife and go hiking. At the time, his wife, who holds a doctorate in law, was living in the Himalayas as part of her ETH Master's in Development and Cooperation, where she was evaluating decentralisation programmes in villages on behalf of Helvetas. Meanwhile, Mussgnug, who had previously completed his degree in mechanical engineering at the Karlsruhe Institute of Technology (KIT), had been working in ETH Professor Meboldt's Product Development Group (PDZ) since 2012 and wanted to take a few weeks' holiday in Nepal. But barely had he arrived when his wife introduced him to Helvetas employee Jürg Merz – and, just like that, the idea for MITO was born.

"Its meaningfulness is its main appeal."Moritz Mussgnug

"At the time, I was responsible for the interdisciplinary Design and Technology Lab run by ETH and the Zurich University of the Arts," explains Mussgnug. "Mechanical engineering students work on a project there for three months together with art university students and an industry partner." The "nut project", as Mussgnug calls it, was perfectly suited to the Design and Technology Lab. "Though Helvetas is not a classical industry partner, this project shows how we can successfully cooperate with a NGO", he says.

Technically challenging project

Even while Mussgnug was still hiking in Nepal, preparations were getting underway in Zurich for the project, which was christened 'MITO' after the Nepal word for "good, tasty". "It was really easy to find students to work on the project," says Mussgnug. "Its meaningfulness is its main appeal."

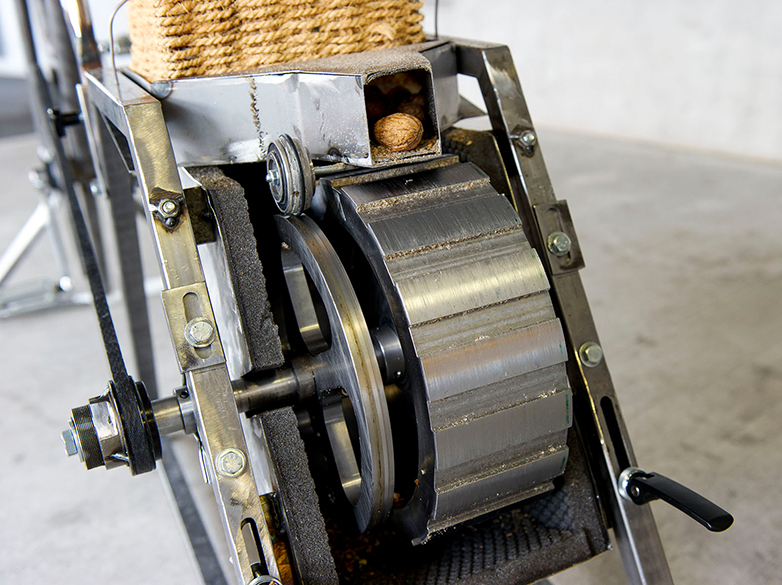

The project is also challenging on a technical level. Most processes use differences in density to separate the shell from the nut before the oil is pressed. However, the densities of the shell and nut in Nepali walnuts are too similar, while the shell is four-times harder than a Swiss walnut shell, leading the project participants to destroy several nut crackers in their first attempts. In addition to the crusher that breaks open the nuts, a complex sieving process was also required to gradually separate the nut from the shell. Together with microscopic examinations, analyses of the nut fat at ETH's Laboratory of Food Biochemistry helped in the search for a solution.

To ensure the machine would work not only under laboratory conditions but also in Nepali mountain villages, it had to be sufficiently robust. Several project participants therefore travelled to Nepal to investigate the living conditions and needs of the people living there. The result was a bicycle-operated machine that cracks the nuts 10 times faster than cracking them by hand. The plan is to take this prototype to Nepal in summer 2017 and test it on the ground. If everything goes to plan, the Nepali farmers will not only be able to produce oil for their own consumption, but also to sell additional quantities and use the proceeds to put their children through school, for example.

Developing ideas together

Mussgnug derives the energy for his numerous projects from the work itself. "Getting new things to work interests me." And, ideally, he likes to tackle these new projects with other people. "I like working in teams to develop ideas together and effect change." It's therefore fitting that his startup Memox offers multifunctional workshop solutions, including presentation equipment, whiteboards and cube seats. MITO also connects people across continents and could significantly improve the Nepali people's quality of life. Even Mussgnug's doctoral thesis uses eye-tracking technology to determine from eye movement how we can improve the interaction between users and products.

Mussgnug is yet to decide what he will do after his doctoral project, which he hopes to finish in autumn 2017. But if all goes according to plan and the PDZ succeeds in winning other projects like MITO, he can certainly imagine staying at ETH. "The PDZ is very interested in further projects with NGOs. And for me personally, working on such basic needs really motivates me."