At the cutting edge of the architecture of the future

The Master of Advanced Studies ETH in Architecture and Digital Fabrication is a new continuing education programme initiated by the National Centre of Competence in Research (NCCR) Digital Fabrication and ETH Zurich. From September, students from all over the world will be able to study innovative methods of construction and design.

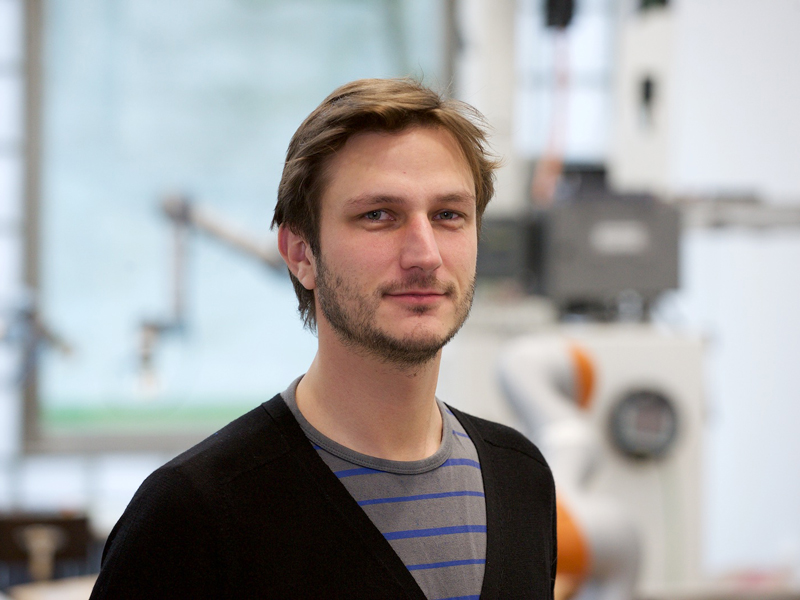

Theory and its application combined - that is what the Master of Advanced Studies (MAS) ETH in Architecture and Digital Fabrication promises to deliver. "We want to train a new generation of architects who will work in a different way compared to the past," says Philipp Eversmann, architect and Head of Education, as he explains the purpose of the MAS study programme.

Students on the 12-month full-time course will be taught the fundamental methods and technologies of digital fabrication and how they can be applied in architecture. The continuing education programme is being offered by Gramazio Kohler Research within the framework of the external pageNational Centre of Competence in Research (NCCR) Digital Fabrication at ETH Zurichcall_made. The plan is for students to not only attend teaching modules but to also take part in joint workshops with the doctoral students at the NCCR and in research projects.

"The MAS programme is geared towards architects and engineers who want to learn more about innovative techniques for construction and design," explains the Head of Education. They are required to have either a university degree in architecture or civil engineering at Master level that is recognised by ETH Zurich, or an equivalent qualification such as a Bachelor degree and two years' professional experience. They are also specifically required to have excellent technical and design skills which should be demonstrated in a portfolio of work.

Change in the manufacturing process

"Not only will the design process be digitised in the future, but so will the manufacturing process," says Eversmann, describing this crucial paradigm shift. Just as the drawing board has long since given way to CAD software, so too could robots have an integral role to play on the building site of the future.

Their task would be to produce and assemble innovative materials and components. "Whereas the shape and size of bricks were designed to suit humans, in future we'll be able to plan and construct in entirely different dimensions," explains Eversmann. The new materials and fabrication processes will open up hitherto unimaginable design opportunities. They also offer the potential for developing more efficient building and construction processes, thereby reducing the use of resources.

That is why the scientists at the NCCR Digital Fabrication are primarily studying the consequences and potential of innovative fabrication processes, the interaction between digital and material processes and the question of how robots could be integrated in a construction site. After all, to give just a couple of examples, not every building material that is invented on screen is as strong in practice as it was hoped, and robots with all-terrain capabilities would need to be developed before they could be used on building sites.

Partnership between robotics and architecture

The NCCR is focusing especially on interdisciplinary cooperation. The NCCR Digital Fabrication brings together the fields of architecture, structural design, electrical engineering, mechanical engineering, robotics and materials and computer science. The researchers work together to study and develop innovative planning and construction processes in architecture. What is special about this NCCR is that the research findings are tested and enhanced directly on full-size prototypes.

For example, researchers from the NCCR Digital Fabrication are directly involved in the construction of the modular research and innovation building, external pageNESTcall_made on the Empa campus in Dübendorf. The foundation stone for this project, which is being run jointly by Empa and Eawag, with support from industry and public funds, was laid last summer. The structural framework, what is called the Backbone, was designed by the architects' practice of Professors Fabio Gramazio and Matthias Kohler.

Construction of the Backbone is expected to be completed this year. Various different research groups will subsequently be able to put their findings about sustainable construction and energy technologies into practice here, building them into modules where they can be tested 1:1 in real-life conditions.

The researchers at the NCCR should soon also be able to carry out their work in a teaching and research building that has been created using digital fabrication methods. The Arch_Tech_Lab on the ETH Hönggerberg campus is scheduled for completion in summer 2016. The NCCR already has research facilities available for non-standard architectural fabrication processes where different methods can be designed and tested.

Deadline for applications: 30 April

Anyone interested in the MAS programme can submit their application immediately. A maximum of 18 students will be able to enrol on this continuing education programme, being offered now for the first time.

The closing date for applications is 30 April 2015. The MAS programme will begin on 14 September 2015. The language of instruction will be English.

You can find more details about the programme and how to apply external pageherecall_made.

Picture Gallery

-

Philipp Eversmann, Head of Education, NCCR Digital Fabrication. (Photo: NCCR Digital Fabrication) -

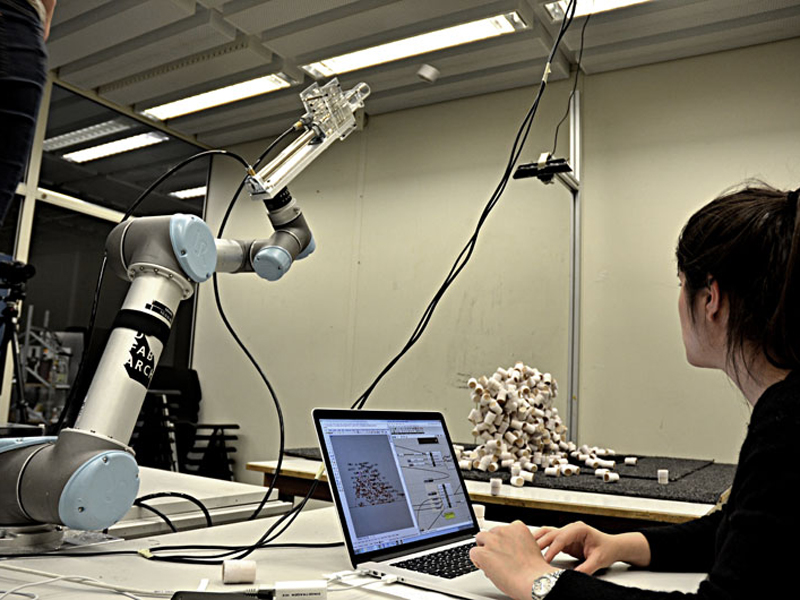

"Complex Timber Structure": designed digitally and built by robots. (Photo: ETH Zurich/ Gramazio Kohler Research) -

Students can apply what they have learnt directly at the NCCR Digital Fabrication. (Photo: ETH Zurich/ Gramazio Kohler Research)