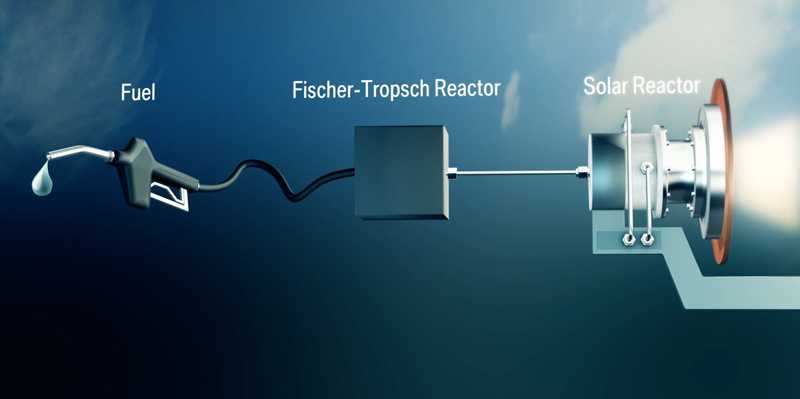

The entire production path of “solar” kerosene

With the first ever production of synthesized “solar” jet fuel, the EU-funded SOLAR-JET project has successfully demonstrated the entire production chain for renewable kerosene obtained directly from sunlight, water and carbon dioxide (CO2), therein potentially revolutionizing the future of aviation. This process has also the potential to produce any other type of fuel for transport applications, such as diesel, gasoline or pure hydrogen in a more sustainable way.

Several notable research organizations from academia through to industry (ETH Zürich, Bauhaus Luftfahrt, Deutsches Zentrum für Luft- und Raumfahrt (DLR), ARTTIC and Shell Global Solutions) have explored a thermochemical pathway driven by concentrated solar energy. A new solar reactor technology has been pioneered to produce liquid hydrocarbon fuels suitable for more sustainable transportation.

“Increasing environmental and supply security issues are leading the aviation sector to seek alternative fuels which can be used interchangeably with today’s jet fuel, so-called drop-in solutions”, states Dr. Andreas Sizmann, the project coordinator at Bauhaus Luftfahrt. “With this first-ever proof-of-concept for ‘solar’ kerosene, the SOLAR-JET project has made a major step towards truly sustainable fuels with virtually unlimited feedstocks in the future.

The SOLAR-JET project demonstrated an innovative process technology using concentrated sunlight to convert carbon dioxide and water to a so-called synthesis gas (syngas). This is accomplished by means of a redox cycle with metal-oxide based materials at high temperatures. The syngas, a mixture of hydrogen and carbon monoxide, is finally converted into kerosene by using commercial Fischer-Tropsch technology.

“The solar reactor technology features enhanced radiative heat transfer and fast reaction kinetics, which are crucial for maximizing the solar-to-fuel energy conversion efficiency” said Professor Aldo Steinfeld, leading the fundamental research and development of the solar reactor at ETH Zürich.

Although the solar-driven redox cycle for syngas production is still at an early stage of development, the processing of syngas to kerosene is already being deployed by companies, including Shell, on a global scale. This combined approach has the potential to provide a secure, sustainable and scalable supply of renewable aviation fuel and more generally for transport applications. Moreover, Fischer-Tropsch derived kerosene is already approved for commercial aviation.

“This is potentially a very interesting novel pathway to liquid hydrocarbon fuels using focussed solar power”, said Professor Hans Geerlings at Shell. “Although the individual steps of the process have previously been demonstrated at various scales, no attempt had been made previously to integrate the end-to-end system. We look forward to working with the project partners to drive forward research and development in the next phase of the project on such an ambitious emerging technology.”

SOLAR-JET (Solar chemical reactor demonstration and Optimization for Long-term Availability of Renewable JET fuel) was launched in June 2011 and is receiving financial support from the European Union within the 7th Framework Programme for a duration of four years. In a first step, the technical feasibility of producing solar kerosene was proven. In the next phase of the project, the partners will optimise the solar reactor and assess the techno-economic potential of industrial scale implementation. The outcomes of SOLAR-JET will put Europe to the forefront of research, innovation and production of sustainable fuels directly from concentrated solar energy.